Checking Out the Perks of Membrane Switches for Modern Electronics

The expedition of membrane switches in contemporary digital devices supplies a fascinating viewpoint on their myriad advantages, especially in terms of layout versatility, sturdiness, and cost-effectiveness. As industries proceed to evolve, the duty of membrane switches in boosting user experience and operational effectiveness warrants better evaluation.

Benefits of Membrane Layer Buttons

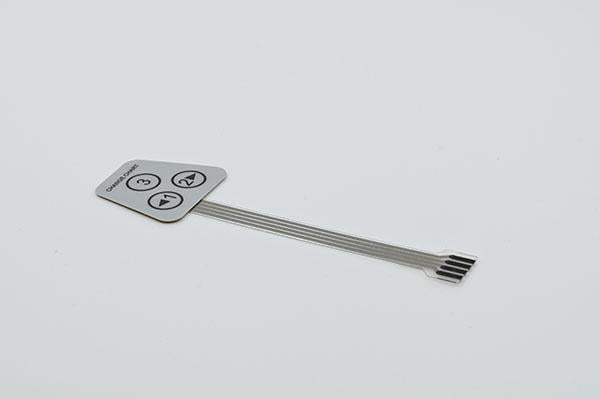

Membrane layer switches are progressively preferred in modern-day electronics due to their various advantages. Among the main advantages is their compact layout, which allows for space-efficient assimilation right into various devices. This slim account not just preserves area however likewise adds to the total aesthetic appeal of digital products.

Another benefit is their toughness. Membrane switches are generally immune to moisture, dirt, and pollutants, making them perfect for use in environments where direct exposure to extreme problems is an issue. This resistance expands the life-span of the switches, lowering the demand for regular replacements and upkeep.

Moreover, membrane switches over deal superb tactile responses, enhancing user experience. The tactile response is frequently created to supply a gratifying feeling upon activation, which can boost user contentment and performance.

Additionally, the manufacturing process of membrane switches is cost-effective, permitting lower production prices compared to standard mechanical switches. This affordability makes them appropriate for a variety of applications, from consumer electronics to commercial machinery.

Layout Adaptability and Personalization

The design adaptability and modification alternatives provided by membrane layer switches further improve their allure in modern electronic devices. These switches can be tailored to fulfill details visual and useful requirements, permitting makers to create gadgets that align carefully with brand name identification and user choices. With different alternatives in terms of shades, shapes, and dimensions, membrane layer buttons can seamlessly incorporate right into varied product layouts, whether for customer electronics, industrial applications, or medical devices.

In addition, the capability to incorporate graphics and signs straight onto the switch surface area enhances use while minimizing the requirement for extra labeling. This integration not just streamlines manufacturing processes yet also adds to a sleeker overall look. The layout can be further customized with attributes such as backlighting, responsive comments, and multi-layer building and constructions, offering enhanced user communication.

Sturdiness and Ecological Resistance

Furthermore, membrane layer switches can be engineered to be chemically immune, making them appropriate for applications in commercial settings where direct exposure to solvents and cleaning up agents prevails. The encapsulation of electronic elements within the membrane structure provides added defense against ecological stress and anxieties, making certain reliable performance even in challenging problems.

Along with physical sturdiness, membrane switches over exhibit superb resistance to UV light, protecting against destruction and staining gradually (membrane switch). This particular is particularly beneficial for exterior applications, where prolonged direct exposure to sunshine can jeopardize other button types

Inevitably, the sturdiness and ecological resistance of membrane changes make them an optimal selection for a vast array of contemporary digital gadgets, from clinical devices to customer electronic devices, ensuring consistent performance and customer complete satisfaction throughout numerous applications.

Cost-Effectiveness in Manufacturing

Cost-effectiveness in manufacturing is a significant benefit of membrane switches, making them a preferred option for suppliers in numerous markets. The production process of membrane layer changes typically includes less materials view it now contrasted to conventional buttons, which lowers raw product costs. This structured production process not only conserves money however also decreases waste, aligning with contemporary sustainability objectives.

Furthermore, membrane buttons can be produced using automated strategies, permitting high-volume result with reduced labor prices. The combination of advanced printing technologies better enhances efficiency, enabling manufacturers to attain complex styles and functionalities without incurring substantial added expenses. This scalability makes sure that manufacturing can adjust to altering market demands without compromising quality or boosting expenses.

Additionally, the lightweight nature of membrane layer changes adds to set you back savings in delivery and handling, as well as in the overall layout of digital gadgets. By eliminating cumbersome elements, suppliers can maximize the total product layout, thereby improving market competitiveness. In general, the cost-effectiveness of membrane changes not just benefits suppliers economically yet additionally promotes technology and rapid item advancement in the dynamic landscape of modern-day electronic devices.

Applications in Numerous Industries

Flexibility attracts attention as a characteristic of membrane layer buttons, permitting them to discover applications across a vast range of industries. In the healthcare market, these buttons are indispensable to clinical devices, providing user-friendly user interfaces for devices like infusion pumps and analysis equipments. Their resistance to dampness and very easy cleaning make them perfect for atmospheres requiring rigorous hygiene requirements.

In the automobile sector, membrane layer switches contribute to the performance of control panels and control panels, offering a smooth, modern look while guaranteeing sturdiness versus rough problems. Their lightweight layout likewise supports general car efficiency.

Additionally, commercial machinery utilizes membrane layer buttons for operational controls. Their robust nature and personalized functions satisfy the certain requirements of varied applications.

Verdict

To conclude, membrane layer changes deal considerable advantages for modern electronics, consisting of design flexibility, durability, and cost-effectiveness. membrane switch. Their customizable attributes and resistance to click this environmental elements make them suitable for a large variety of applications throughout numerous markets. As technological needs continue to progress, the versatility and performance of membrane layer switches placement them as an important component in improving user experience and driving find out here advancement within the affordable landscape of digital devices